The Singapore Armed Forces (SAF) has scored a world's first with its newly commissioned Underground Ammunition Facility (UAF).

Touted as the world's most modern underground ammunition facility and the first large-scale underground containerised facility to be designed and developed within a densely developed and urbanised area, the UAF is a revolutionary engineering achievement that took more than 10 years to complete.

"The facility that we are standing in today is a reality because we dared to pursue a bold new solution to overcome one of our perennial constraints," said Minister for Defence Teo Chee Hean, who officiated at the commissioning ceremony on 7 Mar.

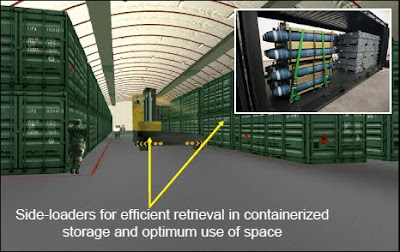

Apart from safety and operational requirements, efficient land use and space management were key considerations in the design of the UAF.

When the existing Seletar East Ammunition Depot was identified for redevelopment by the Urban Redevelopment Authority (URA), the Ministry of Defence recognised that replacing it with a traditional above-ground ammunition depot would not be optimal in land-scarce Singapore.

This is because for a conventional ammunition depot, large tracts of land surrounding it are required to be "sterilised" - not used for any other purpose - in order to ensure a safe distance from the depot to public access areas.

"The UAF requires 90 per cent less land to be sterilised when compared with a traditional above-ground ammunition depot of similar capabilities," said Mr Teo.

"This is because the inherent strength of the granite formation here at the Mandai Quarry provides natural fortification and its hard granite walls contain the risks associated with ammunition storage."

Mr Teo (second from left) unveiling the commemorative plaque during the UAF commissioning ceremony.

Mr Teo and other invited guests seeing how the mechanised system in the facility works.

By building this underground facility, about 300 hectares of land, equivalent to 400 football fields or half of Pasir Ris New Town, have been freed up for other use.

The UAF is equipped with the latest ammunition storage technology and systems to serve as a one-stop operations centre for storage and supply of ammunition in the SAF.

Gone are the days of having to manually strap ammunition pallets onto transporters to move out of the depot.

Mechanised for easy retrieval and processing, containers can now be easily loaded onto commercial trailers.

By leveraging on IT and automation, about 20 per cent less manpower is needed to operate the facility. More ammunition can also be moved to the troops in a much shorter time, and in the exact configuration required for the mission.

This is done by storing ammunition loads for specific missions in ready-to-move standard containers.

Another benefit is the natural insulation provided by the granite caverns, resulting in a 50 per cent reduction in the energy required for cooling compared to a conventional depot.

The engineering team that undertook this massive project comprised members from the SAF, the Defence Science & Technology Agency (DSTA), and SembCorp Design and Construction.

They carried out extensive simulation studies and scale-testing of shock waves in a mixed media of soil and rock to validate key design aspects, setting new international standards in underground storage safety in the process.

Their research findings have been since presented at international conferences and published in leading scientific journals.

"Because they dared to dream, think deep and break new ground, we have created more space for our defence, while freeing up more precious land for Singapore," said Mr Teo.

Other research centres that collaborated on the project include the Nanyang Technological University, the National University of Singapore, Sandia National Laboratories in the United States, FOI - the Swedish Defence and Research Establishment, and the Norwegian Defence Estate

(mindef.gov.sg)

No comments:

Post a Comment